Home > Product > SPG Induction heating machine > SPG-03-10 series 200K--1.5MHZ |

SPG-03-10 series 200K--1.5MHZ |

- SPG-03-ⅡHF Induction heater

(1) SPG-03A-Ⅱ and SPG-03-Ⅱ

(2) Maximum input power 3KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 300—700KHZ

(5) Used for small parts heating

- SPG-03B-Ⅲ HF Induction heater

(1) SPG-03AB-Ⅲ and SPG-03B-Ⅲ

(2) Maximum input power 3KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 600—1100KHZ

(5) used for Brazing of saw tip

- SPG-06-I HF Induction Heater

(1) SPG-06A-I and SPG-06-I

(2) Maximum input power 6.6KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 200—500KHZ

(5) Used for small parts heating and melting

- SPG-06 with 1m flexible coil

(1) SPG-06 with 1m flexible coil

(2) Maximum input power 6.6KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 300—700KHZ

(5) Used for small parts heating and melting

- SPG-06-ⅡHF Induction Heater

(1) SPG-06A- Ⅱ and SPG-06-Ⅱ

(2) Maximum input power 6.6KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 300—700KHZ

(5) Used for small parts heating and melting

- SPG-06B-Ⅲ HF indction heater

(1) SPG-06B-Ⅲ

(2) Maximum input power 6KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 600—1100KHZ

(5) used for Brazing of saw tip

- SPG-10-Ⅱ HF induction heater

(1) SPG-10A-Ⅱ and SPG-10-Ⅱ

(2) Maximum input power 10KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 200—500KHZ

(5) Used for small parts heating and melting

- SPG-10B-Ⅱ High Frequency Induction Heater

(1) SPG-10B-ⅡInduction heater

(2) Maximum input power 10KW

(3) Input : 220V 50 or 60HZ single phase

(4) Output frequency 200—500KHZ

(5) Used for small parts heating and melting

- SPG-10-Ⅱ Multi-material melting type High Frequency Induction Heater

(1) SPG-10-Ⅱ multi-material melting type induction heating machine

(2) Maximum input power 10KW

(3) Input : 220V 50 or 60HZ single phase

(4) Melting of all kind materials

- SPG-10-Ⅱ Multi-material melting type High Frequency Induction Heater

(1) SPG-10-Ⅱ multi-material melting type induction heating machine

(2) Maximum input power 10KW

(3) Input : 220V 50 or 60HZ single phase

(4) Melting of all kind materials

Main specifications:

model |

Max. input power |

Output frequency |

input |

Auxiliary function |

|

SPG-03-I |

3KW |

200-500KHZ |

220V single phase 50 or 60HZ |

Normal type |

|

SPG |

With timer |

|

|||

SPG-03-II |

200—700KHZ |

Normal type |

|

||

SPG |

With timer |

|

|||

SPG-03B-III |

0.6—1.1MHZ |

With heating head |

|

||

SPG-03AB-III |

With timer and heating head |

|

|||

SPG-06-I |

6.6KW |

200—500KHZ |

Normal type |

||

SPG |

With timer |

||||

SPG-06-Ⅱ |

6.6KW |

200—700KHZ |

Normal type |

||

SPG |

With timer |

||||

SPG-06B-Ⅲ |

6KW |

0.5—1.1MHZ |

With heating head |

||

SPG-06AB-Ⅲ |

With timer and heating head |

||||

SPG-10-Ⅱ |

10KW |

200—500KHZ |

Normal type |

||

SPG |

With timer |

||||

Main applications and characteristics:

SPG-03 SPG-06 and SPG-10-II series are suitable for many applications, for example, (1)Brazing of the saw tips (2)Heating of wire smaller than 1mm (3)floating melt for institute or college research and so on.

Due to the adopting of our third generation inverting control technology and the MOSFET power components, these series machines are characterized not only with high frequency up to 1.1MHZ output, but also with high reliability. It is especially suitable to heat tiny parts and wires.

Advantages and applications of models with Timer function:

1. Heating power, retaining power, heating time, retaining time can be preset and adjusted, this makes it possible to control the heating curve and heating time.

2. It is suitable to use in the repeated heating or high speed heating of small parts;

3. When using in brazing, with proper timing parameters, rapid heating and retaining can be achieved to keep the temperature while the brazing material is melted and then to let the brazing material spread smoothly to form good joint.

Advantages and applications of SPG-03B-III and SPG-06B-Ⅲ with heating head:

1. The heating head weights 3.5KG,and size is 14×14×9.3cm,with 2 meters long cable between generator.

2. The light and small heating head is especially suitable for the applications in which the parts are stationary and the heating head is moved to fit the place.

Working theory and structure

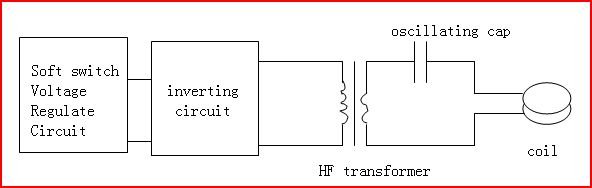

In SPG-03、SPG-06 and SPG-10-II series machines, series oscillating circuit is applied, through high frequency transformer, low voltage and high current power is output to go through the induction coil. The main oscillating structure is as follows:

Inside these series machines, MOSFET and our third generation inverting control technology has been used, that is the soft and dual control and inverting technology. In this technology, output power and frequency can be controlled and adjusted separately, MOSFET and soft switching control technology are used in the high frequency switching circuit to control the output power. In the inverting circuit, the MOSFET and frequency tracing circuit is applied to achieve high speed and accurate soft switching control. The adoption of new technologies makes it possible to output the 1.1MHZ high frequency power supply.

Inside these series machines, oscillating cap is connected to the secondary coil of the transformer, so the voltage on the primary coil of the transformer is low and problems caused by high voltage such as sparks and insulations are solved thoroughly to increase the reliability and quality of the machine. At the same time, the transformer is light and small sized with low energy consuming.